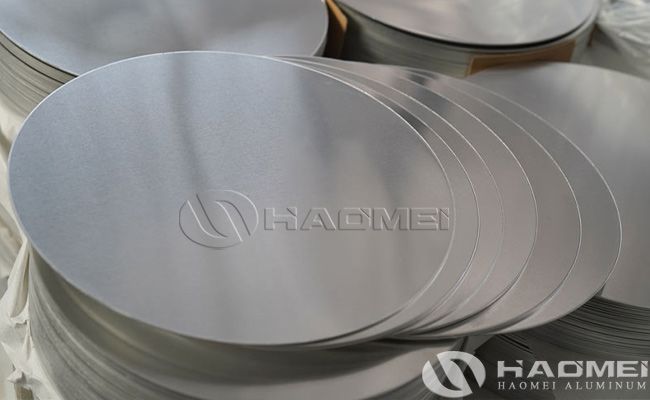

1000 series aluminum circles refer to a series of aluminum alloys with aluminum as the main component, typically containing no less than 99% aluminum. 1000 series aluminum alloys are characterized by good corrosion resistance, electrical and thermal conductivity, but relatively low strength, primarily used in applications where high strength is not required. Common 1000 series aluminum discs include 1050, 1060, 1070 and 1100, they have wide applications in many fields, such as industrial manufacturing, home appliances, kitchenware, and transportation. Due to their good processing performance, aluminum discs can be manufactured into products of various shapes and sizes through stamping, cutting, and other processes.

The core grades of 1000 series aluminum discs include:

1050 aluminum discs: Aluminum content ≥99.5%, meeting international standards.

1060 aluminum discs: Aluminum content ≥99.6%, mature production process, significant cost advantage.

1070 aluminum discs: Aluminum content ≥99.7%, high plasticity, excellent electrical and thermal conductivity.

1100 aluminum discs: Aluminum content ≥99.0%, containing trace amounts of copper (0.05%-0.20%) to enhance ductility and formability.

1000 series aluminum circles: Flexible specifications, customizable production available:

Thickness range: 0.2mm to 5mm, meeting diverse application needs.

Diameter range: 20mm to 1900mm, covering small components to large structural parts.

Characteristics of 1000 series aluminum circles:

1. High aluminum content:

1000 series aluminum alloys typically have an aluminum content of over 99%, exhibiting excellent purity.

2. Good corrosion resistance:

Due to the natural oxide layer of aluminum, 1000 series aluminum alloys exhibit excellent corrosion resistance in many environments.

3. Excellent electrical conductivity:

This series of aluminum alloys has high electrical conductivity, suitable for electrical applications.

4. Good thermal conductivity:

1000 series aluminum alloys have superior thermal conductivity, suitable for applications requiring heat dissipation.

5. Ease of machining:

Aluminum discs are easily processed into various shapes through cutting, stamping, and stretching, adapting to diverse manufacturing needs.

6. Lightweight:

Aluminum's low density allows 1000 series aluminum alloys to reduce overall weight in structural applications.

7. Recyclability:

Aluminum is highly recyclable, meeting environmental requirements and contributing to sustainable development.

Application areas of 1000 series aluminum circles:

1. Home appliance industry:

Used in manufacturing appliance housings, heat sinks, and other components.

2. Transportation:

Used in automotive and aircraft parts to reduce overall weight and improve fuel efficiency.

3. Kitchenware:

Used in making cookware and tableware due to its excellent thermal conductivity and corrosion resistance.

4. Electrical industry:

Used in conductive components such as cable connectors and radiators.

5. Construction industry:

Used in building decoration materials such as aluminum window frames and aluminum curtain walls.

6. Medical devices:

Used in the housings and structural components of some medical devices.

7. Packaging materials:

Used in food packaging, pharmaceutical packaging, etc., due to its excellent sealing and corrosion resistance.

In conclusion, 1000 series aluminum discs have become an indispensable material in many industries due to their excellent performance and wide range of applications.