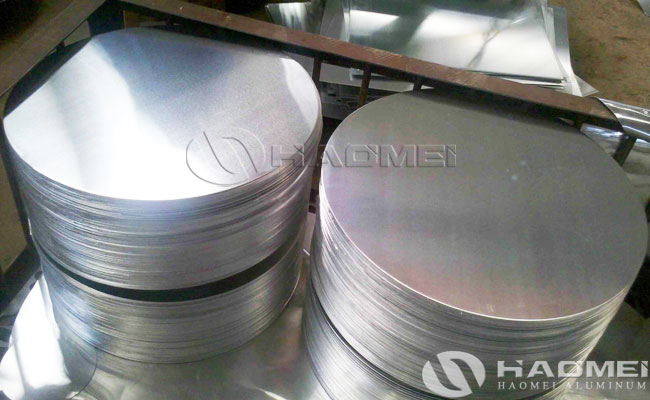

Circular aluminum discs are used for cooking utensils, lamp stretching cover, traffic signs, road signs, aluminum cans and tank heads, etc. In order to ensure the excellent quality of the circle aluminum discs, aluminum discs manufacturers usually set up special quality inspection positions during the production. The staff will also use professional tools to carefully inspect the quality of the aluminum discs. The accuracy of aluminum discs is a very important item among various quality inspection items. So, when you want to perform effective accuracy inspection on high-quality aluminum discs, what aspects should the staff pay attention to in the process of inspecting the accuracy of aluminum discs?

What should be paid attention to when testing the accuracy of circular aluminum discs?

1, Pay attention to the use of intact measuring tools

When inspecting aluminum circles, workers need to use professional measuring tools. As the aluminum discs are very thin, any defect in the measuring tool will affect the measurement results to a certain extent. Therefore, in order to ensure accurate detection of the accuracy of the aluminum circle discs, the staff must pay attention to protecting the measurement tools. Not only cannot the detection tools be stored near corrosive gases, nor can they be inspected by non-metering protection personnel. When it is disassembled, an intact measuring tool must be used to test the accuracy of the aluminum circle.

2, Be careful to remove the burrs on the surface first

circular aluminum disc have many production processes in the production process, and after each process is completed, tools need to be used for quality inspection. When testing the accuracy of aluminum discs during the production process. The presence of burrs on the surface of the aluminum circle will affect the accuracy of the detection. So, in order to avoid affecting the quality detection accuracy of the aluminum disc, the burrs on the surface of the aluminum circle should be removed first, and then the quality of the aluminum discs should be tested.

The accuracy of the circular aluminum discs is an important indicator to measure its quality, so professional tools need to be used to measure the accuracy of the aluminum disc during the production process. In order to ensure that the high-quality and high-priced aluminum discs can be accurately measured, the staff should pay attention to the use of intact measuring tools when performing accuracy testing, and also pay attention to remove the burrs on the surface of the aluminum discs.