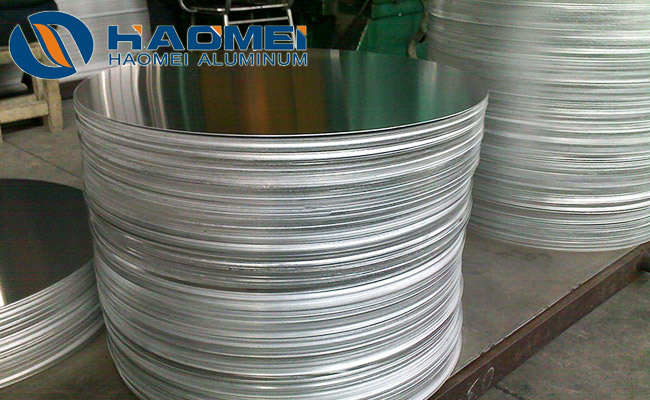

Aluminium circle for pot sheets 1060, 1100 and 3003 supplied by Haomei has the features of high deep drawing and spinning performance and low cost. Haomei have introduced three new automatic deflection production lines, including two 1.3m wide production lines with a nominal pressure of 80t, one 1.6m wide production line with a nominal pressure of 160t. The total monthly output is 1500 tons. Haomei aluminum has 120 sets of supporting molds, with the diameter range of 100mm to 1000mm.

The aluminum circle sheet produced by Haomei has high quality because we have rich experience on aluminum circle processing and export. The production of aluminium circle for cookware is aluminum ingot melting into aluminum water. The foundry is made of 7-10 mm aluminum plates. 7-10 mm aluminum plate is rolled to the required thickness by cold rolling mill, for example 0.5-1 mm. Cut the finished aluminum coil to the required width, and generate a circular line to obtain the correct diameter of the aluminum wafer. The produced aluminum wafer are widely used to make basin, wok, rice cooker, pizza pot, electric frying pan, electric pressure cooker and restaurant cooker.

At present, Haomei mainly produces 1000 series and 3000 series aluminum discs. The technical parameters of the aluminium circle for pot sheets are 0.5-6mm in thickness and 100-1200mm in diameter. The elongation of the produced aluminum wafer can reach 30% - 35%, the grain size is first grade, the surface of the aluminum circle sheet is flat without scratches, clean without oil stain, the edge is smooth without burr, which conforms to RoHS and reach environmental protection standards, and has excellent deep drawing and spinning performance. It is widely used in cooking utensils, electrical appliances, utensils, traffic signs, lamps, building materials, automobiles and other industries. In addition, the factory specially employs technicians with rich production experience, and actively summarizes the experience of previous end customers, strictly controls the production process, and keeps improving the products, effectively avoiding problems such as orange peel, square edge and lotus leaf edge caused by deep drawing or spinning in the later processing of customers.