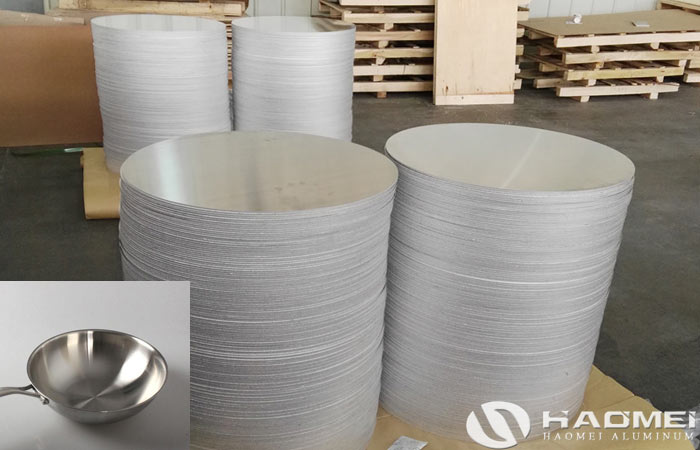

Aluminium circle for making pot has aluminum 1050, 1060, 1070, 1100, 3003 and 5052 aluminum discs with 0.4 -5mm thickness and 20-1200mm diameter. Generally, cooking pots, soup pots or pans, etc., are mostly made of stainless steel or aluminum alloy materials, while pots made of aluminum circle alloy are lighter in weight and lower in manufacturing cost, so the pot on the market is basically made by aluminium circle material.

The characteristics of the aluminum pot are excellent heat distribution and the pot body is lighter. Hot rolled DC 3003, 1060, 1100 aluminium circle are always used for making pot that needs to be deep drawing. Whether you want to use 3000 or 1000 series is mainly to see what kind of pot you want to make. The 3000 series aluminium circle has better hardness than 1000 series aluminium circles after stretched. While casting (many people call cold rolled) CC aluminum circle is easy to pull (pull crack) after stretch, and the oxidation effect is not as good as DC. Generally, 3000 series 3003 aluminium circle DC is used in the kitchen utensils.

Aluminum alloy is an excellent heat conductor. Aluminum has 5 times faster thermal conductivity than iron and 9 times faster than stainless steel. Due to the excellent thermal conductivity of aluminium circle for making pot, heat is evenly distributed on the entire surface of the pot at the fastest speed, foods of different shapes can be heated uniform due to the high thermal conductivity of aluminum.