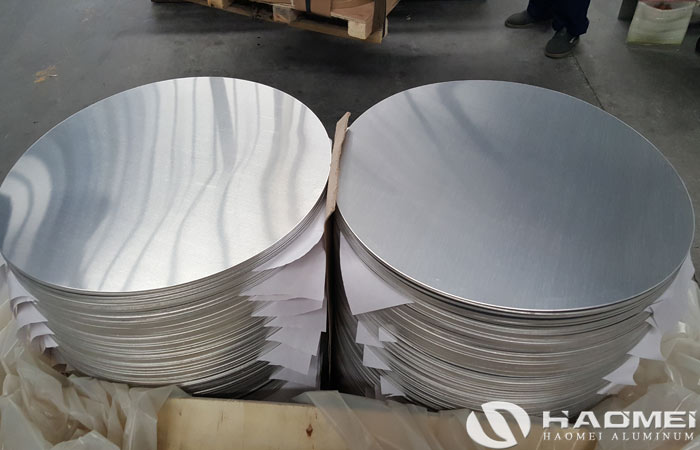

3003 aluminum circle for cooking utensils has thickness of 0.4-5mm and diameter of 20-1200mm with excellent deep drawing, spinning performance. The service life of 3003 aluminum alloy is relatively long, and the cookware made of 3003 aluminum circle is non-toxic and tasteless, not easy to corrode, high in strength, long in service life, and safe and hygienic.

Aluminum cooking utensils are generally light in weight, has thermal conductivity, is not easy to rust, is more durable, but is not suitable for cooking some foods with strong acidity and alkalinity, otherwise the aluminum element in the cookware will react and will dissolve and pollute food. The 3003 aluminum circle is a commonly used product in the aluminum-manganese alloy series. Thanks to the manganese alloy element, 3003 aluminum has excellent rust-proof properties and is also known as rust-proof aluminum. The formability, the solubility, and the corrosion resistance of 3003 aluminum discs are all good. Thus, 3003 aluminum circle can be sued to process kitchenware such as pan, pot, non-stick pan, pressure, etc.

3003 aluminum circle for cooking utensils hot rolled has better stretch performance than the cold rolling, the hardness of 3000 series aluminum discs is better than 1000 series. After stretch process, the cold rolled aluminum circle is easy to burst, and the oxidation effect is not as hot rolling aluminum discs. So the general kitchen utensils are processed by hot rolling 3003 aluminum circle.