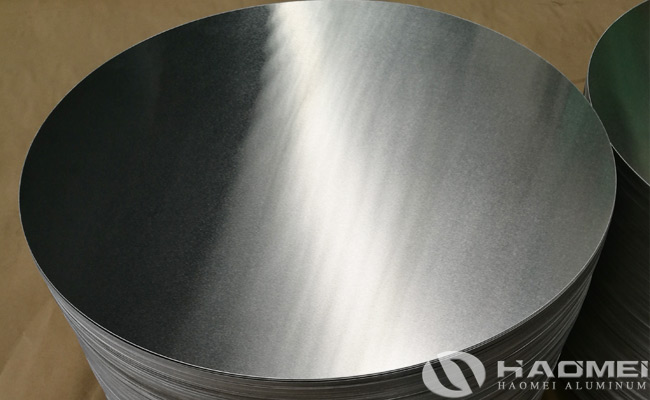

1050 aluminum circle cc dc has the advantages of light weight, good thermal conductivity, good corrosion resistance, good strength and deep drawing performance. In addition, the 1050 aluminum circle has low price which will save purchase cost for the enterprise and it is easy to carry out various deep processing, especially for various cooking utensils and lamps.

The DC and CC of 1050 aluminum circle is about the processing. The cost of hot rolling is higher than that of cast rolling. But the difference between them is not only the production cost. The maturity of the hot rolling process and the level of equipment control are far higher than those of cast-rolled 1050 aluminum circle products, and the hot rolling is rolled within the recrystallization temperature range of aluminum alloys, and there is no limitation of alloy composition. In other words, the product can cover all aluminum alloy series, such as 1000 series, 3000 series, 5000 series, 2000 series, 7000 series, etc.

Cast-rolling is a new type of technology developed after the 1970s. Its advantage is that molten aluminum directly passes through a rotating crystallizer to directly produce plate and strip products. It has considerable equipment and investment than hot rolling. However, because it is an emerging technology, the process defects of crystallization and casting have not been solved in the world. Therefore, the casting and rolling mill can only produce 1000 series pure aluminum and a few 3000 series alloy products.

Haomei supply 1050 aluminum circle cc dc with different specification which will cover the demand of different industry, and our DC CC aluminum circle can ensure high quality, clean surface, accurate thickness and neat edge cutting.