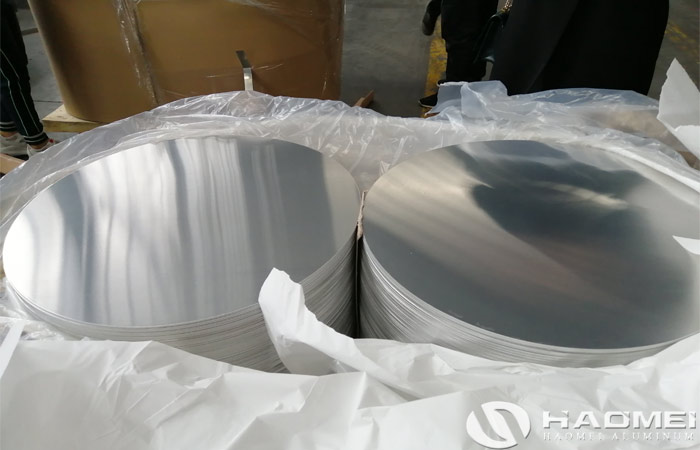

Dc aluminum circle manufacturers are mainly use hot-rolled aluminum coil substrates with the grain size well controlled, the produced aluminum circle is suitable for deep-draw drawing. In Haomei, aluminum circles of various diameters can be provided according to user requirements. After continuous stamping, the aluminum circle product has the advantages of accurate dimensions, smooth and flawless surface, good anodizing effect, and high elongation. It is mainly used in lamps, kitchenware, electronic and electrical enclosures, etc.

The alloy of dc aluminum circle are 1060, 1070, 1100, 3003 and 5052, the thickness is 0.4-5mm, the diameter is 20-1200mm. And the temper is basically O, H12 and H14, the most usually used temper is O, which need to have better elongation properties for deep drawing. The DC aluminium circle has the advantages of high surface finish, no scratches and high elongation. At the same time, it has strong mechanical properties and ductility, and good oxidation effect. DC aluminum discs circle is suitable for stamping and drawing. The elongation of CC aluminum circle is lower than that of DC aluminum circle.

Hot rolling can improve the processing performance of aluminum alloys, that is, the coarse grains in the as-cast state are broken, significant cracks are healed, casting defects are reduced or eliminated, the as-cast structure is transformed into a deformed structure, and the processability of the dc aluminum circle is improved. So the aluminum circle DC can be applied to drawing, deep drawing, spinning, oxidation and other subsequent processes.