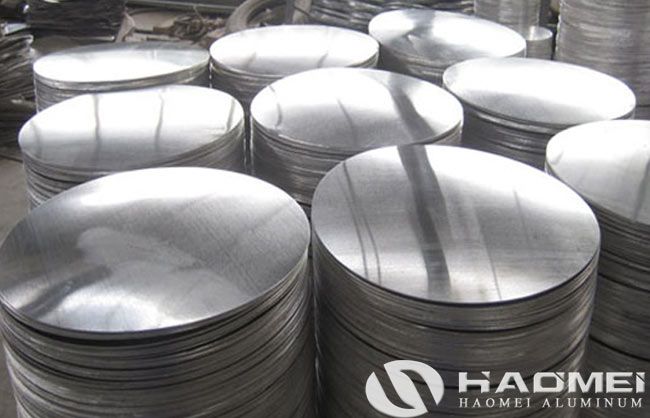

In the wave of global lightweight industrial upgrades, 1000 series pure aluminum and 3000 series aluminum-manganese alloy aluminium discs for sale have become core materials in food packaging, building decoration, electronic appliances and other fields with their unique performance combination. As a local professional aluminum disc supplier and exporter, we Haomei Aluminum deeply analyze the technical characteristics and application scenarios of these two series to help you accurately match the needs.

1. 1000 series pure aluminum discs: high purity and multiple applications

1000 series aluminum discs are based on industrial pure aluminum, with an aluminum content of ≥99%. Common grades include 1050, 1060 (purity 99.6%), 1070 and 1100 (purity 99.0%). Its core advantages are:

- Extreme processing performance:

The elongation can reach more than 25%, which is suitable for complex forming processes such as deep drawing and spinning. For example, the thickness tolerance of 1060 aluminum discs after cold rolling is controlled at ±0.02mm, and the surface roughness Ra≤0.8μm, which can be directly used in capacitor housing manufacturing.

- Excellent corrosion resistance:

The corrosion rate in a neutral environment is only 1/5 of that of ordinary steel. It is widely used in food can heads, pharmaceutical packaging aluminum foil and other fields. A European food company uses 1100 aluminum discs to manufacture milk powder cans, which have passed FDA food contact certification and extended the shelf life to 24 months.

- High conductivity:

The conductivity of 1060 aluminum discs is ≥61% IACS, which is often used for soft connections of new energy vehicle batteries. The temperature range is -40℃ to 150℃, and it has passed UL 94 V-0 flame retardant certification.

Typical application scenarios:

- Cookware manufacturing: After anodizing, the hardness of 1060 aluminum discs reaches 2H, which is made into non-stick pan substrates, and the thermal conductivity uniformity is 30% higher than that of stainless steel.

- Architectural decoration: The reflectivity of 1100 aluminum discs is ≥85%, which is used for traffic signs and curtain wall decoration, and the outdoor service life exceeds 10 years.

- Electronic devices: 1050 aluminum discs (purity 99.5%) are made into LED lamp heat sinks with a thermal conductivity of 200W/(m・K), which is 40% lower than copper material cost.

2. 3000 series aluminum-manganese alloy discs: the golden balance of corrosion resistance and strength

3000 series aluminum discs are based on aluminum-manganese alloy (manganese content 1.0%-1.5%), with representative grades 3003 and 3004. Its technical characteristics include:

- Enhanced corrosion resistance:

No red rust in the salt spray test (NSS) in marine climate for 500 hours, far exceeding 1000 series aluminum discs products. A Southeast Asian port uses 3003 aluminum discs to manufacture cargo identification signs, which are maintenance-free for 5 years.

- Medium strength characteristics:

Tensile strength 120-160MPa, 30% higher than pure aluminum, while maintaining good formability. The cupping value of 3003 aluminum discs is ≥9.0mm (thickness 2.0-4.0mm), and can be processed into complex shapes such as pressure cookers and baking trays.

- Environmental compatibility:

RoHS compliant, widely used in cosmetic packaging and medical equipment components. A German daily chemical company uses 3004 aluminum discs to manufacture perfume bottle caps, and the color stability after surface anodizing is more than 10 years.

Typical application scenarios:

- High-end cookware: 3003 aluminum discs can be made into 0.8mm ultra-thin pressure cooker substrates through a special cold rolling process (total processing rate of more than 80%), and the thermal expansion coefficient matches the stainless steel bottom, solving the delamination problem of traditional composite bottoms.

- Industrial equipment: 3004 aluminum discs (H24 state) are used for chemical storage tank linings, with better acid and alkali corrosion resistance than 316L stainless steel, and a 25% reduction in cost.

- Lightweighting of automobiles: 3003 aluminum discs are made into body trim strips, the surface electrophoretic coating adhesion reaches 5B level, and the weather resistance passes the QUV 3000-hour test.

Process innovation and quality control system

- Precision processing technology

Cold rolling process: Using a 20-roller Sendzimir rolling mill, the thickness tolerance of 3003 aluminum discs is controlled at ±0.015mm, meeting the needs of precision parts such as electronic shielding covers.

Hot rolling process: Through double-stage heat treatment (615℃×10h+445℃×8h), the grain size of 3003 aluminum discs is refined to ASTM 6 level, and the earing rate during deep drawing is ≤3%, significantly reducing the scrap rate.

- Surface treatment solution

Anodizing: film thickness 8-25μm, hardness ≥3H, salt spray resistance test 1000 hours, suitable for high-end cookware and lamp housings.

Painting process: Fluorocarbon coating (PVDF) is used, which has a weather resistance of 25 years and is widely used in building curtain walls and outdoor billboards.

- Testing and certification system

Mechanical properties: tensile strength, elongation, cupping value and other indicators have passed the ISO 6892-1 standard test.

Environmental certification: The product has passed international certifications such as FDA (food contact), RoHS (restriction of hazardous substances), EN 573 (EU building materials).

As a source aluminum discs manufacturer, we provide:

- Full specification coverage:

Diameter 100-1600mm, thickness 0.5-6.5mm, support single-sided/double-sided lamination, paper addition and other special processes.

- Quick response capability: 7-day delivery for regular orders, 48-hour response for emergency orders, annual production capacity of 50,000 tons, which can meet the batch demand of markets such as Europe, America, and Southeast Asia.

- Technical support system:

Provide full-process services from material selection to mold design, such as customizing 3003 aluminum discs (diameter 1200mm, thickness 4.0mm) for a Middle Eastern customer for the inner tank of a solar water heater, which has passed DNV GL classification society certification.

Choose our aluminum discs, you will get:

✅ Cost advantage: large-scale production reduces procurement costs by 15%.

✅ Quality assurance: ISO 9001:2015 certification system, batch qualification rate >99.8%, and provide third-party test reports.

✅ Innovative solutions: such as 3003 aluminum discs and stainless steel composite processes, which have both corrosion resistance and thermal conductivity, with a thermal conductivity of 150W/(m・K), and have been used in high-end uncoated cookware.

1000 series and 3000 series aluminium discs for sale have become key materials for global industrial upgrades due to their high purity, corrosion resistance and processing flexibility.